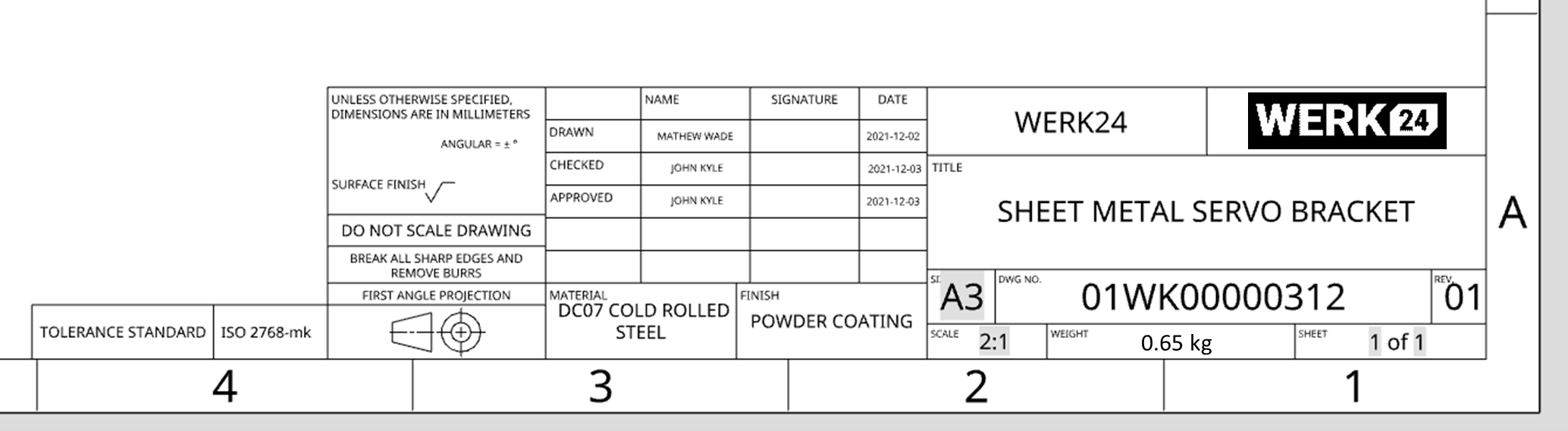

The Title Block contains the “Meta Data” of the drawing. For example, it tells us the number and name of the drawing.

You can leverage this information with what you need to know to improve the User Interaction.

The title block is normally placed in the bottom right of the drawing frame, and it should contain the following information:

The name of the company or organization to which the component belongs. You can add the name of the company or business where this technical drawing was created.

The Logo of the company or organization to which the component belongs.

The title of the drawing should be concise and to the point. Using the words 'or' or'for' in the drawing title is not recommended.

Drawing number is generally a unique filing identifier. It is the number assigned to the drawing generated for a particular component. It may be unique in relation to the part number. As a rule, each organization has its numbering framework for specialized drawings.

Revision Number is the count of current revisions of the part.

When a component is modified, it is recommended to modify the existing engineering drawing to incorporate the changes. Once the changes have been made, the existing drawing is superseded, replaced by the new version. In a Drawing Management System, these kinds of changes are completed within a document workflow and often require engineering review and approval.

During the life of a product, parts that are used for many years, may be revised several times to improve performance or reduce cost. After a drawing change request is made, the drawing is modified. Any change to a drawing after release, shall be recorded in the Revision History Block.

When a drawing is first issued, it is called revision zero or dash (-), and the revision block is empty. As each revision is made to the drawing, an entry is placed in the revision block. This entry will provide the revision number, a summary of the revision, the date of the revision, and approver name.

As the component is modified, and the drawing is updated to reflect the changes, the revision number is increased by one, and the revision number in the revision block is changed to indicate the new revision number. For example, if a Revision 2 drawing is modified, the new drawing showing the latest modifications will have the same drawing number, but its revision level will be increased to 3. The old Revision 2 drawing will be maintained in the filing system for reference.

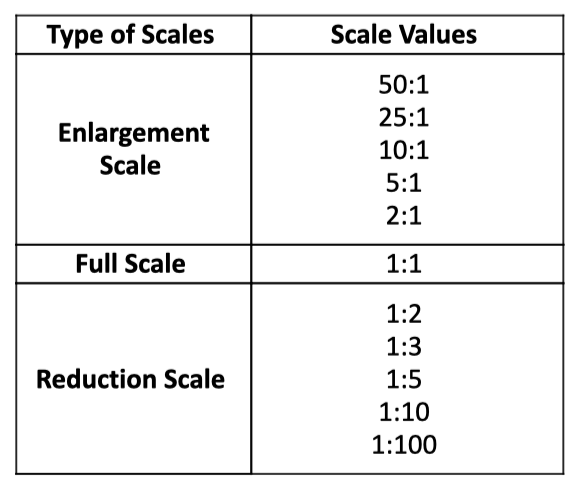

Drawings may be made actual size, or they may be made smaller or larger than the actual size of the object. A drawing that is twice the actual size of the part would show a scale of 2 = 1 or 2:1. A drawing made half the actual size of a part would be in a scale of 1/2 = 1 or simply 1:2.

The size of the form for the original document, e.g. A4, A3. If a technical drawing is drawn in different sizes with respect to the original size, you can understand it from this area.

Either first or third angle, generally shown symbolically (Explained in “Projection Method“ sections)

Signature or initials of the draftsman, checker, approving officer, and issuing officer, with the respective dates. This section shows the information about the person performing various actions on the drawing.

Material used for the manufacturing of the part.

In the table of European standards for metallic materials, specifications for seamless and welded steel pipes and pipes products, wire and wire products, forgings, sheets, strips and definition of steel products are presented.

ASTM specifications represent a consensus among producers, specifiers, fabricators, and users of steel mill products. ASTM’s designation system for metals consists of a letter (A for ferrous materials) followed by an arbitrary sequentially assigned number. These designations often apply to specific products, for example A548 is applicable to cold-heading quality carbon steel wire for tapping or sheet metal screws.